Coking: Equipment

|

Courtesy of “The Making, Shaping, and Treating of Steel” |

Equipment

Combustion Technology

Energy Consumption

Process Description

R&D Trends

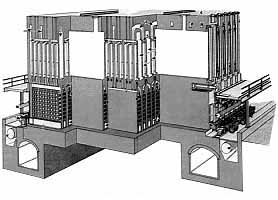

A coke oven battery consists of 10-100 individual coke ovens with batteries of 45 or more being preferred in the U.S. The long thin coking chambers (Height 6-22 ft., Length: 3-52 ft, Width: 1-2 ft) alternate with the heating chambers so that there are heating chambers on both sides of each coking chamber to provide even heating. This alternating row of heating and coking chambers sits atop regenerative chambers that recover the flue gas heat for preheating the combustion air. The burners/regenerators are alternated on a 15-30 minute cycle determined by the need to maintain temperature control within the coking chambers. On top of the coke oven battery are coal charging cars. On the pusher side of the battery is the large pusher/leveler that levels the input charge and then pushes the hot coke out of the oven. On the coke side of the oven, quench cars take the incandescent coke to the quenching system.