Coking: R&D Trends

|

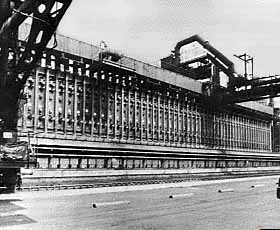

Pusher side of a by-product coke oven battery. |

Equipment

Combustion Technology

Energy Consumption

Process Description

R&D Trends

The iron and steel industry would need to invest $4-6 billion in the their coke oven batteries to replace or repair current capacity to bring them into compliance with environmental regulations. Of the 79 batteries operating, about half are more than 30 years old. Work is underway to minimize leakage from doors and to improve the process of chemicals recovery and air and process water cleanup. Systems to utilize lower quality coals for coking are also of interest, such as the continuous form-coking process. However, the focus of R&D in the industry is more toward reducing or eliminating the coke requirements in iron-making through pulverized or granular coal injection in blast furnaces (PCI/GCI) or completely new direct iron/steel making technologies that could utilize coal or some other fuel directly.