Secondary Finishing: R&D Trends

|

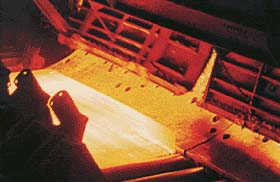

Courtesy of the Gas Research Institute |

Equipment

Combustion Technology

Energy Consumption

Process Description

R&D Trends

Improvements in reheating practice are centered on temperature uniformity, scale free heating, rapid heating rates, and temperature equalization and localized heating.

Temperature Uniformity – Skid Mark Eraser

Technology:

Skid Mark Eraser, Salem Corp.

Description:

High convection burner placed in furnace bed at intervals along skid

Phase II – Bench-scale laboratory program ending

Phase II – Installation at test site

Comments:

Market potential pusher furnace

Walking beam furnaces have lower temperature differences at skid marks

Gauge control corrects for skid marks on modern rolling mills

Scale Free Heating

Technology:

Scale Free Heating

Description:

Various reheat furnace concepts under development

Comments:

Limited market due to trend towards hot charging and direct rolling. Concern about retrofit capability.

Rapid Heating (BG and Air Products lines)

Technology:

Rapid Heat Technologies – British Gas Research Institute

Description:

High convection heating of steel

Comments:

Applied mainly to forging furnaces in North America

Technology:

Rapidfire Technology – Air Products and GRI

Description:

Direct oxyfuel flame impingement heating of workpiece.

Comments:

Potential for application in the following areas:

Thin/intermediate slab heating

Preheating of slabs for warm charging

Heating of transfer bars

Interstand heating in hot mills

Heating of Strip

Temperature Equalization and Localized Heating

Technology:

Radiative Converter – Tokyo Institute of Technology

Description:

Bench-scale laboratory program

Slab furnace is slightly larger than slab dimensions with stainless mesh on sides

Hot gas jet impinges on center of slab furnace; stainless mesh on sides of slab furnace is heated by the hot gases

Edge of slab heated by radiation from stainless mesh

Comments:

Improvement on heat shields for direct charging of slabs

Slab edge heating application.

Low NOx Burner Development

GRI has supported the development of the STAR burner concept (Staged Air Recirculating Burner). Hauck Manufacturing, Arthur D. Little, and Massachusetts Institute of Technology have developed this burner system with air staging and flue gas recirculation that can remove 90% of the NOx of conventional burners. The system is being scaled up to 15-20 MMBtu and is being adapted to cold-air firing or integral recuperation.

Steel Mill Process Heating Technology Study, Hatch Associates, GRI-95/0106, Gas Research Institute