Blow Thru Space Heaters

Application

Application

- Industrial and Commercial Space Heating

Overview

Using Blow-Thru, High Efficiency Space Heaters is a very popular and versatile method for heating large warehouses, manufacturing plants, and other types of commercial/industrial facilities. The hallmarks of these direct-gas fired heating systems are energy savings, thermal comfort and improved indoor air quality. They can be used to heat buildings from 10,000 sq.ft. to over 1 million sq.ft., with ceiling heights from 12 ft to over 50 ft.

How it works

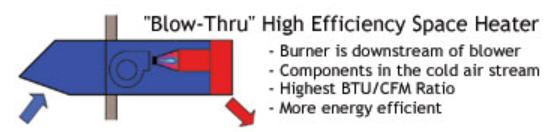

This direct-fired heater technology uses a “blow-thru” gas burner/blower arrangement where the burner is downstream of the blower. (Direct gas-fired make-up air (MUA) and Recirculation (80/20) type heaters use a conventional draw-thru technology.) The blow-thru design is important for a number of reasons: it locates critical components in the cold air stream for longer service life; achieves the highest BTU/CFM ratio; allows this design be certified for the highest possible temperature-rise and outlet temperature rating of 160°F. The maximum temperature rating is crucial because it translates into lower horsepower motors, less outside air and reduced energy costs.

Advantages

Thermal Comfort and Improved IAQ

These units can be used to heat facilities with either no powered exhaust or with a lot of exhaust. As a non-recirculating design, the burner always heats 100% outside air. Indoor air quality (IAQ) benefits are significant because these systems do not recirculate potentially contaminated inside air. When properly applied, this design will neutralize the building’s natural air infiltration and heat the minimum volume of outside air. The induced rotating air effect created by the unit’s high air velocity creates very effective air movement in the building, thereby reducing stratification and temperature differences in the facility. This eliminates higher ceiling temperatures and cold dock door areas. Wall-to-wall and floor-to-ceiling temperature variances of three to five degrees are typical, compared to ten to fifteen degrees for many other heating systems.

Lowest Installed Cost

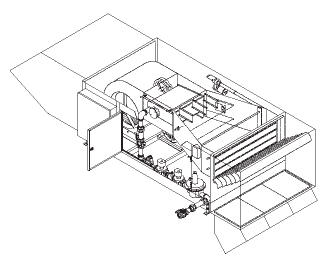

This heater type is competitively priced, easy to install and simple to start-up so it often has the lowest initial “first cost”. A few, compact, lightweight space heaters can be installed just about anywhere, including on the roof, under the roof, through the wall or pad mounted outside the building. Building owners value the additional usable floor and vertical racking space they get with these heaters. The “thru-wall” installation option is very popular because equipment can be kept off the roof, reducing both installation and construction costs. Being a direct gas-fired heater, they do not require a flue stack, thus eliminating those costly roof penetrations.

Lowest Operating Cost

How can heating 100% outside air with direct-fired space heaters be more energy efficient and offer lower operating costs? The answer is simple; all commercial/industrial heating systems actually do heat outside air entering the building via natural infiltration, through open dock doors or ventilation requirements. The blow-thru, technology with its certified, maximum 160°F temperature rise/outlet temperature matches the infiltration and heats the minimum volume of outside air by supplying more BTU/CFM than any other heating system. High efficiency, blow-thru space heaters operate intermittently and run at capacity only when required as compared to other much bigger heating systems with large fans that run continuously. Building studies are available that document very balanced building temperatures with 30 % to 70% energy savings versus the other types of direct and indirect gas-fired space heating equipment.

Manufacturers

Cambridge Engineering, Inc

Cambridge Engineering, Inc

17825 Chesterfield Airport Rd.

Chesterfield, MO 63005

Telephone: 800-899-1989, 636-532-2233

Heating capacity is 300,000 to 3,000,000 BTUs at 1800 to 14,000 CFM

Guidelines for selecting an industrial space heating system, by Ken Williams of Cambridge Engineering.

Review 3 Case Studies provided by Cambridge Engineering where buildings with various types of heating systems were instrumented and monitored and then compared against similar buildings in similar climates with Cambridge Blow-Thru Space Heater systems.

Cambridge -v- Make Up Air Systems – Northern Distribution Centers

Cambridge -v- Air Turnover System – Side-by-side warehouse tenants in PA

Cambridge -v- MUA w/Recirculation – Northeast Warehouses

Go to Cambridge’s web site at www.cambridge-eng.com

Source: Ken Williams, Cambridge Engineering, edits by Bob Fegan 12/2003; images from Cambridge Engineering

© 2008 Energy Solutions Center400 N. Capitol Street NWWashington, DC 20001 All rights reserved. Legal Contact our webmaster