Heat Treating: Combustion Technology

Equipment

Combustion Technology

Energy Consumption

Process Description

R&D Trends

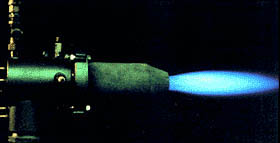

A wide variety of burner configurations are used in aluminum heat treating. The most important requirement of heat treating burners is that they can be precisely controlled and they deliver a uniform temperature distribution to the metal charge. The basic categories include those listed below.ConventionalConventional burners are the most widely used burners in aluminum furnaces. These burners are either used to heat the refractory brick which radiates energy to the aluminum charge, or to transfer heat directly to the aluminum charge through flame impingement.Direct flame impingement increases the heat transfer efficiency, but also increases the metal oxidation loss. These burners are typically non-premixed diffusion burners without air or fuel staging or regeneration.Radiant TubesRadiant tubes are used in applications where low emissions and reduced metal oxidation are of importance. Radiant tubes combust the natural gas inside an inner tube which then passes the combustion gases across an outer tube. The outer tube is made of high radiation emitting material which transfers the heat via radiation to the intended application. The combustion and combustion gases are contained entirely inside the radiant tube and are never allowed to come in contact with the aluminum charge.

Courtesy of Eclipse Combustion