Why Natural Gas?

Fuel Oil

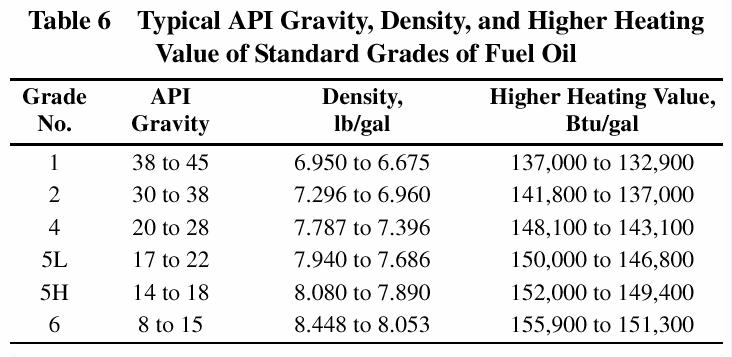

1 Gallon of #2 Fuel Oil = about 140,000 BTUs

1 Gallon of #2 Fuel Oil = about 1.4 CCF Natural Gas

1 CCF Natural Gas = about 0.7142 Gallon #2 Fuel Oil

Fuel Cost Conversion Formulas:

Cost per Gallon Fuel Oil x 0.7142 = about Cost per CCF Natural Gas

Cost per CCF Natural Gas / 0.7142 = about Cost per Gallon #2 Fuel Oil

Examples:

If Fuel Oil costs $1.50/Gallon, the BTU equivalent cost of Natural Gas is $1.50 x 0.7142 = $1.07 per CCF.

If Natural Gas costs $1.00 per CCF, Fuel Oil would have to cost ($1.00 / 0.7142 = $1.40 per Gallon) to match the BTU cost of Natural Gas.

Liquid Fuels

Significant liquid fuels include various fuel oils for firing combustion equipment and engine fuels for on-site energy systems. Liquid fuels, with few exceptions, are mixtures of hydrocarbons derived by refining crude petroleum. In addition to hydrocarbons, crude petroleum usually contains small quantities of sulfur, oxygen, nitrogen, vanadium, other trace metals, and impurities such as water and sediment. Refining produces a variety of fuels and other products. Nearly all lighter hydrocarbons are refined into fuels (e.g., liquefied petroleum gases, gasoline, kerosene, jet fuels, diesel fuels, and light heating oils). Heavy hydrocarbons are refined into residual fuel oils and other products (e.g., lubricating oils, waxes, petroleum coke, and asphalt).

Crude petroleums from different oil fields vary in hydrocarbon molecular structure. Crude is paraffin-base (principally chain-structured paraffin hydrocarbons), naphthene- or asphaltic-base (containing relatively large quantities of saturated ring-structural naphthenes), aromatic-base (containing relatively large quantities of unsaturated, ring-structural aromatics), or mixed- or intermediate- base (between paraffin- and naphthene-base crudes). Except for heavy fuel oils, the crude type has little significant effect on resultant products and combustion applications.

Types of Fuel Oils

Fuel oils for heating are broadly classified as distillate fuel oils (lighter oils) or residual fuel oils (heavier oils). ASTM Standard D 396 has specifications for fuel oil properties that subdivide the oils into various grades. Grades No. 1 and 2 are distillate fuel oils. Grades 4, 5 (Light), 5 (Heavy), and 6 are residual fuel oils. Specifications for the grades are based on required characteristics of fuel oils for use in different types of burners.

Grade No. 1 is a light distillate intended for vaporizing-type burners. High volatility is essential to continued evaporation of the fuel oil with minimum residue. Grade No. 2 is a heavier distillate than No. 1. It is used primarily with pressure-atomizing (gun) burners that spray the oil into a combustion chamber. The atomized oil vapor mixes with air and burns. This grade is used in most domestic burners and many medium-capacity commercial-industrial burners.

A dewaxed No. 2 oil with a pour point of 58°F is supplied only to areas where regular No. 2 oil would jell.

Grade No. 4 is an intermediate fuel that is considered either a heavy distillate or a light residual. Intended for burners that atomize oils of higher viscosity than domestic burners can handle, its permissible viscosity range allows it to be pumped and atomized at relatively low storage temperatures.

Grade No. 5 (Light) is a residual fuel of intermediate viscosity for burners that handle fuel more viscous than No. 4 without pre-heating. Preheating may be necessary in some equipment for burning and, in colder climates, for handling. Grade No. 5 (Heavy) is a residual fuel more viscous than No. 5 (Light), but intended for similar purposes. Preheating is usually necessary for burning and, in colder climates, for handling.

Grade No. 6, sometimes referred to as Bunker C, is a high-viscosity oil used mostly in industrial heating. It requires preheating in the storage tank to permit pumping, and additional preheating at the burner to permit atomizing.

Low-sulfur residual oils are marketed in many areas to permit users to meet sulfur dioxide emission regulations. These fuel oils are produced (1) by refinery processes that remove sulfur from the oil (hydrodesulfurization), (2) by blending high-sulfur residual oils with low-sulfur distillate oils, or (3) by a combination of these methods. These oils have significantly different characteristics from regular residual oils. For example, the viscosity-temperature relationship can be such that low-sulfur fuel oils have viscosities of No. 6 fuel oils when cold, and of No. 4 when heated. Therefore, normal guidelines for fuel handling and burning can be altered when using these fuels.

Fuel oil grade selection for a particular application is usually based on availability and economic factors, including fuel cost, clean air requirements, preheating and handling costs, and equipment cost. Installations with low firing rates and low annual fuel consumption cannot justify the cost of preheating and other methods that use residual fuel oils. Large installations with high annual fuel consumption cannot justify the premium cost of distillate fuel oils.

Characteristics of Fuel Oils

Characteristics that determine grade classification and suitability for given applications are:

- viscosity

- flash point

- pour point

- water and sediment content

- carbon residue

- ash

- distillation qualities or distillation temperature ranges

- specific gravity

- sulfur content

- heating value

- carbon-hydrogen content

Not all of these are included in ASTM Standard D 396.

Viscosity is an oil’s resistance to flow. It is significant because it indicates the ease at which oil flows or can be pumped and the ease of atomization. Differences in fuel oil viscosities are caused by variations in the concentrations of fuel oil constituents and different refining methods.

Flash point is the lowest temperature to which an oil must be heated for its vapors to ignite in a flame. Minimum permissible flash point is usually prescribed by state and municipal laws.

Pour point is the lowest temperature at which a fuel can be stored and handled. Fuels with higher pour points can be used when heated storage and piping facilities are provided.

Water and sediment content should be low to prevent fouling the facilities. Sediment accumulates on filter screens and burner parts. Water in distillate fuels can cause tanks to corrode and emulsions to form in residual oil.

Carbon residue is obtained by a test in which the oil sample is destructively distilled in the absence of air. When commercial fuels are used in proper burners, this residue has almost no relationship to soot deposits, except indirectly when deposits are formed by vaporizing burners.

Ash is the noncombustible material in an oil. An excessive amount indicates the presence of materials that cause high wear on burner pumps.

The distillation test shows the volatility and ease of vaporization of a fuel.

Specific gravity is the ratio of the density of a fuel oil to the density of water at a specific temperature. Specific gravities cover a range in each grade, with some overlap between distillate and residual grades. API gravity (developed by the American Petroleum Institute) is a parameter widely used in place of specific gravity. It is obtained by the following formula: (1) where Sp Gr at 60/60°F is the ratio of the mass of a given volume of oil at 60°F to the mass of the same volume of water at 60°F. The API gravity of water at 60°F is 10.0.

Air pollution considerations are important in determining the allowable sulfur content of fuel oils. Sulfur content is frequently limited by legislation aimed at reducing sulfur oxide emissions from combustion equipment. These laws require sulfur content to be below a certain level, usually 1.0, 0.5, or 0.3%.

Sulfur in fuel oils is also undesirable because of the corrosiveness of sulfur compounds in the flue gas. Although low-temperature corrosion can be minimized by maintaining the stack at temperatures above the dew point of the flue gas, this limits the overall thermal efficiency of combustion equipment. For certain industrial applications, the sulfur content of a fuel must be limited because of adverse effects on product quality. The applications include direct-fired metallurgy where work is performed in the combustion zone.

Heating value is an important property, although ASTM Standard D 396 does not list it as one of the criteria for fuel oil classification. Heating value can generally be correlated with the API gravity.