Rotary Driers – Continuous, Solid, Heat Sensitive

Rotary Driers – Continuous, Solid, Heat Sensitive

Industry: Fruit and Vegetable Preserving and Specialty Food Mfg (NAICS 3114)

NAICS process:

311411 Frozen Fruit and Vegetables

311421 Canned Fruit and Vegetables

311422 Canned Specialty Products

311423 Dried and Dehydrated Products

Process Brief: Moisture in fruits and vegetables is removed using hot air.

Energy source: Steam/Natural gas

Energy Intensity: 1,400-9,700 Btu/lb of water in the product

Continuous

Rotary driers are used for drying fruits and vegetables, such as cocoa beans, nuts, pomace, and cooked cereals. These foods are solid foods that are small and relatively strong. The drier is a rotating stainless steel cylinder with a slightly (i.e., 5o) inclined axis. The cylinder has internal flights that direct the movement of the product and ensure good mixing and rapid drying. Hot air is generated by blowing hot combustion gases from natural gas burners into the center of the drier or by using air heated indirectly by steam tubes. In some cases, the drier structure is heated by steam jacketing.

These driers are favored for products such as cereals that stick together on belt or conveyor driers. One disadvantage of rotary driers is degradation of some products by impact and abrasion, which precludes the use of this technique for most products.

Batch

Rotary driers are used for drying fruits and vegetables, such as cocoa beans, nuts, pomace, and cooked cereals. These foods are solid foods that are small and relatively strong. The drier is a rotating stainless steel cylinder with a slightly (i.e., 5o) inclined axis. The cylinder has internal flights that direct the movement of the product and ensure good mixing and rapid drying. Rotary driers operated in batch mode tend to be associated with smaller operations and the loading and unloading may be performed manually. These driers are favored for products such as cereals that stick together on belt or conveyor driers.

Vertical Rotary

|

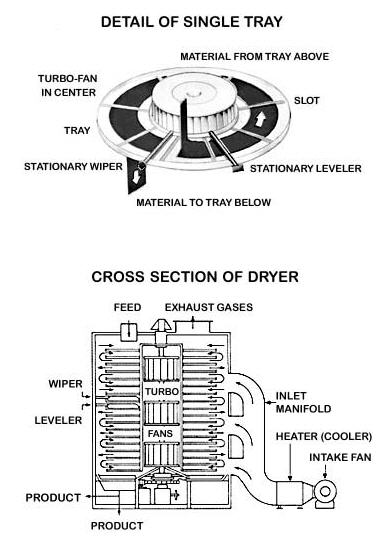

The TURBO-DRYER® consists of a stack of slowly rotating circular trays. Material is fed onto the top tray. After one revolution the material is wiped onto the next lower tray where it is mixed, leveled, and then after one revolution, is wiped to the next tray where the operation is repeated. The trays are contained in an enclosure in which heated air or gas is circulated by internal fans.

Even, thorough, and rapid drying Wyssmont TURBO-DRYER® delivers very uniformly dried product because material is intermittently redistributed with plug-flow operation. Uniform inside temperature or zoned temperature regions. The closest product temperature control of any dryer possible. Can give the lowest residual moisture of any dryer.

Product Quality Gentle handling. Little dust, fines. Little product degradation, even with fragile materials such as crystals and pellets. Provides a free-flowing product when other dryers produce material that cakes or sets-up in containers, silos, or railcars.

Source: http://www.wyssmont.com/pdryer.html

|

|

Manufacturers

Aeroglide Corporation

Mailing Address

P.O. Box 29505

Raleigh, NC 27626-0505

Telephone: 919-851-2000

Web site: www.aeroglide.com

Swenson Technology, Inc.

26000 Whiting Way

Monee, IL 60449-8060 USA

Telephone: 708-587-2300

Web site: www.swensontechnology.com

Wyssmont

1470 Bergen Blvd.

Fort Lee, NJ 07024

Telephone: 201-947-4600

Web site: www.wyssmont.com