Boiler and Steam System

Efficiency Improvement Opportunities

Introduction

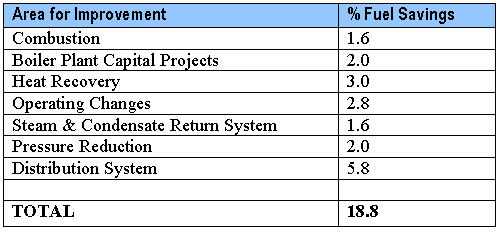

Improvements in efficiency of boiler and steam systems can result in significant operating cost savings. Audits have indicated that 15 – 20% fuel savings can be achieved with a payback period of less than 2 years. In addition, total annual emissions of air pollutants, such as NOx and CO2 are also reduced.

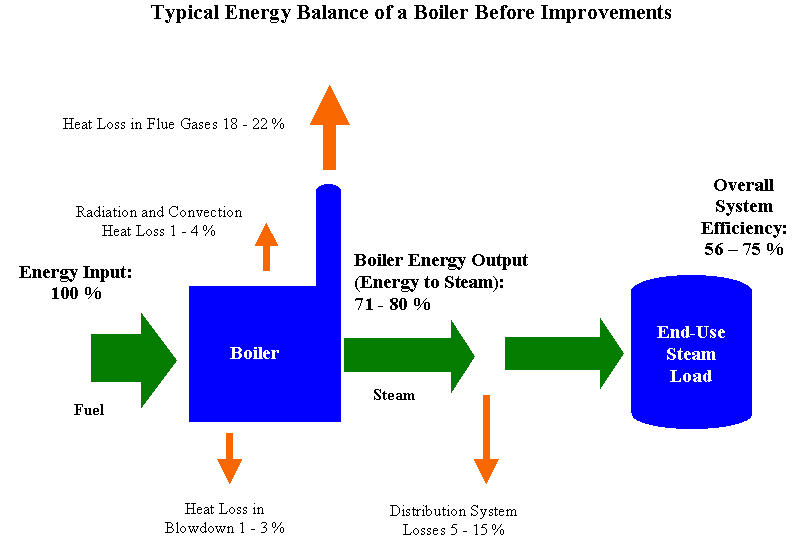

The figure below illustrates typical losses in a boiler/ steam system.

Areas to Improve Energy Efficiency

Boiler Plant

- Reduce Excess Air

- Install Economizer for Preheating Boiler Feedwater

- Reduce Blowdown

- Recover Heat from Blowdown

- Reduce Line Pressure

- Preheat Combustion Air

- Operate System of Boilers at Peak Overall Efficiency

- Minimize Boiler On-Off Operation (e.g. summer boiler)

- Reduce Scale and Deposits (i.e. good water quality)

- Reduce Deaerator Venting

- Regular Maintenance

Distribution System

- Improve Piping Insulation

- Reduce Steam Trap Losses

- Maximize Condensate Return

The following summary of identified energy saving opportunities is based on actual audits of 62 industrial boiler plants with a combined natural gas consumption of approximately 19 billion cubic ft/year:

Note: the above savings exclude electricity, water and chemicals.

(Source: Enbridge Gas Distribution)

For Further Information

- “Guide to Low-Emission Boiler and Combustion Equipment Selection” by C. B. Oland, Date Published: April 2002

Prepared for the U.S. Department of Energy, Office of Industrial Technologies

Prepared by OAK RIDGE NATIONAL LABORATORY

Oak Ridge, Tennessee 37831

managed by UT-BATTELLE, LLC for the

U.S. DEPARTMENT OF ENERGY

under contract DE-AC05-00OR22725

This 170 page document is a thorough presentation of all aspects of boiler emissions and improvement techniques.

Click here to download “Guide to Low-Emission Boiler” 2.0 Meg PDF

- “Boilers and Heaters – Improving Energy Efficiency”; Natural Resources Canada – Office of Energy Efficiency; 2001.This 18 page primer is an excellent introduction to boiler efficiency and methods for determining efficiency. Topics include fundamentals of combustion and heat losses; boiler and heater operational controls; environmental impacts of combustion; combustion regulations; energy management tips.

Click here to download Boilers and Heaters 1.9 Meg PDF

- U.S. Department of Energy, Office of Industrial Technologies, Steam Best PracticesThe “BestPractices” program helps to identify opportunities to save substantial amounts of energy in industrial manufacturing plants. It provides access to Informational resources and tools, technical assistance and demonstration of emerging technologies. BestPractices teams with industrial companies to conduct hands-on energy assessments and training in energy management practices.The website also provides downloads of the following software:Steam System Scoping Tool. This spreadsheet is designed to help steam system energy managers and operations personnel for large industrial plants. The program will profile and grade steam system operations and management. This tool will help you to evaluate your steam system operations against identified best practices.Steam System Assessment Tool. This allows users to assess potential savings from individualized steam-system improvements. Users input data about their plant’s conditions, and the software generates results detailing the energy, cost, and emissions savings that various improvements could achieve.

- U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy,

Steam System Opportunity Assessment for the

Pulp and Paper, Chemical Manufacturing and

Petroleum Refining Industries

- “Council of Industrial Boiler Owners Energy Efficiency Handbook”; 1997.This 63 page handbook provides information on water treatment; combustion; boilers; controls; heat recovery; fans, pumps and other auxiliaries; flue gas treatment; steam systems; compressed air systems; and electrical distribution systems.

Click here to download CIBO Steam Handbook 1.5 Meg PDF

- “An Energy Efficiency and Environmental Primer for Boilers and Heaters”; Natural Resources Canada/Ontario Ministry of the Environment/Union Gas/ Enbridge Gas; 2000.

Click here to see the files that are available for download

- Alliance to Save Energy website: www.ase.org/steamingahead/. The website provides case studies, tip sheets and links.

- Natural Resources Canada – Office of Energy Efficiency website:www.oee.nrcan.gc.ca.