Flash Steam Recovery

Overview

Overview

Flash steam is formed when high pressure/temperature condensate is suddenly decreased in pressure. (See Steam Basics for more information.)

A facility may have two steam operating pressures, such as a high pressure for process loads, and a low pressure for heating water and space heating equipment. If there is enough differential in the steam pressures, about 75 psi, flash steam from the high pressure condensate can be recovered to supply steam to the low pressure steam header.

If not recovered in a flash steam generator, high pressure condensate is either flashed to steam and vented (lost), or may be used in the deaerator to pre-heat boiler feed water. See Deaerator.

The economics of a flash steam recovery system will depend on the amount of flash steam available and how much can be used that is currently not used in applications such as the deaerator.

Operation

In the schematic to the right, the high pressure steam is passed through a PRV (Pressure Reducing Valve) at the top to form low pressure steam. (Example: 100 psi high pressure to 25 psi low pressure.)

High pressure condensate enters the flash steam generator from the left. A rapid drop in pressure flashes some of the condensate to steam that goes up into the low pressure steam header, and the rest becomes low pressure condensate that flows into a pumping steam trap that returns it to the low pressure condensate return line.

A PRV to vent is a safety device to keep the low pressure header from gaining more low pressure steam than it can distribute.

Economics

Click on Image for larger view

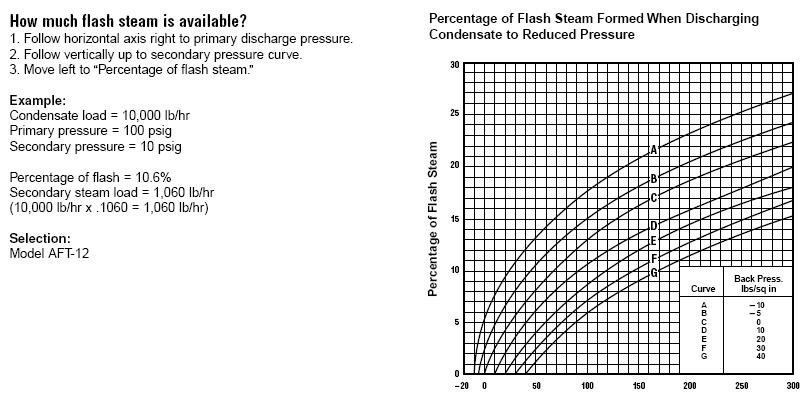

In the above example, 1,060 lbs per hour of steam is recovered. On a BTU basis, this steam is worth at least 1,200 BTUs per pound. When natural gas is $6.00 per million BTUs, the value is at least (1,060 lbs x 1,200 BTUs) / (1,000,000 BTUs x 80% Boiler Efficiency) x $6.00 = $9.54 per hour.

Considering that this steam is already treated, the total value is even higher.

The Formula:

((SH – SL) / H ) x 100 = % Flash Steam

SH = Sensible heat in the condensate at higher pressure before discharge

SL = Sensible heat in the condensate at the lower pressure to which discharge takes place

H = Latent heat in the steam at the lower pressure to which the condensate has been discharged

To determine SH use a Steam Table and know what the condensate pressure is.

For SL, use 180 BTUs for an atmospheric ending pressure, or use a Steam Table

For H, use 970 BTUs per pound at atmospheric ending pressure, or use a Steam Table.

Repeating the above example using the Formula and a Steam Table:

SH @ 100 psi = 308 Degrees F

SL @ 10 psi = 208 Degrees F

H @ 10 psi = 952 Latent Heat BTUs per pound

((308 – 208) / 952) x 100 = 10.5%

More Information

Manufacturers

Armstrong International

PO Box 408

Three Rivers, MI 49093

Telephone:

269-279-3601

Fax: 269-279-3150Go to their web site at www.armstronginternational.com

Spirax Sarco, Inc

1150 Northpoint Blvd.

Blythewood, SC 29016

Telephone:

803-714-2000

Fax: 803-714-2222Go to their web site at www.spiraxsarco.com/us

Recent Comments