Water Heating Technologies

- Booster Heaters for Restaurant Dish washing

- Direct Contact for industrial process

- Tankless Water Heaters developed for Residential use also for dedicated small Industrial Applications

Overview

The heating of water is an energy intensive process in a technology that dates back to the second or third practical use of fire (behind ‘space heating’ and cooking, I assume). Water is the basis for the definition of a BTU. 1 BTU = the amount of energy it takes to raise 1 pound of water, 1 degree Fahrenheit. Since water weighs about 8.34 lbs/gallon, and we like to use it at above 100F, we put a lot of BTUs into our water.

Codes dictate the temperature of water in commercial facilities. For example, hot water for showers may be limited by code to about 110F, where water used for dish washing must be at least 180F or use chemical sanitation. Most facilities operate their water temperature in the 140F range and use mixing valves to reduce the water temperature before distribution (mixing valves are 3 way valves with a hot in, cold in, and mixed outlet) or in the case of dish washing, boost the temperature with a second Booster Heater.

Water heating can be categorized in the following general classes:

- Residential water heaters – tank units typically 30 or 40,000 BTUs/Hour in gas

- Commercial tank water heaters 199,000 BTUs to about 500,000 BTUs/Hour

- Water Heating Boilers (essentially the same as space heating boilers)

- Instantaneous, tank-less, steam convertors

- Direct Contact water heaters (submerged combustion)

- Booster Heaters

- Pool Heaters, snow melt systems and other specialty applications

Residential Water Heaters

Residential water heaters are common in small commercial and industrial office buildings. They are typically 30 or 40 gallons and have BTU ratings that match their size (30,000 BTUs/Hr and 40,000 BTUs/Hr). These units are very low cost and can produce water up to about 150F in volumes of about 20 to 30 gallons per hour.

Commercial Water Heaters

Commercial Water Heaters

Commercial basic tank water heaters are simply heartier versions of the residential units. They often have ratings of 199,000 BTUs/hour as many codes change at 200,000 BTUs/hour and above. They have a storage tank of about 100 gallons and can heat water to about 180F. These units are common in small restaurants, small hotels, and large office buildings.

Water heaters are rated according to their recovery rate, or the number of gallons of hot water they can produce in one hour after their storage tank has been drawn down. This varies with the inlet and outlet water temperatures. The larger the burner, the higher the recovery rate. The larger the storage tank, the more hot water they can provide in the first hour.

The largest tank style water heaters are about 750,000 BTUs/Hour. Most have atmospheric burners (like photo to right). The newer, highest efficiency units have power burners (see AO Smith photo below) and have more elaborate heat exchangers. Some of the new units are barely recognizable as water heaters (see Lochinvar below for example). Look for water pipes, and a flue to be sure!

Units with atmospheric burners only need 0.25 psi (7″) of gas pressure to operate. Higher efficiency units with power burners will typically require at least 0.5 psi (14″) as the gas pressure must work against a little back pressure from the burner blower.

Water Heating Boilers

Water Heating Boilers

When the capacity of tank water heaters is exceeded, water heating boilers are used. Conventional water heating boilers are different than space heating boilers. They tend to have atmospheric gas burners, where boilers generally have powered burners, and operate at lower temperatures. Newer high-efficiency units have power burners, condensing heat exchangers, and operate at temperatures just as high as space heating boilers. Other differences are that water heater boilers are built to take more ‘thermal shock’ due to colder inlet water temperatures and must raise the water to a higher ‘delta T’ (change in temperature), operate without boiler water treatment chemicals, and use external water storage tanks.

A thermostat controls the water temperature in the storage tank, with a circulation pump used to circulate the water between the storage tank and the boiler. A second pump circulates water to the point of use. These systems are generally rated in the 1 – 3 Million BTU/hour range . Storage tanks are large, highly insulated cylinders, and the boilers resemble smaller boxes with gas burners.

Water heating boilers are common in schools, hospitals, and large hotels. By varying the size of the storage tank and the boiler size, a large variety of capacities and demands can be met. For example, a hotel with a high demand in the morning, but little demand the rest of the day, could have a small boiler and a large storage tank. A laundry may have a large boiler and a small storage tank.

Instantaneous, Tankless and Steam Convertors

Instantaneous, Tankless and Steam Convertors

Instantaneous water heaters are also known as tankless, because they heat the water in one pass through the heat exchanger. The heat exchanger may be gas fired or it may be a steam convertor. If gas fired, the applications tend to be very small volumes. Steam convertors on the other hand, tend to be large loads where there is a central boiler – such as institutional and hospitals.

Steam convertors use steam from a central boiler on one side of the heat exchanger, and water on the other side. The convertor may also be inside a tank or include a separate tank to add storage capacity, depending on the design of the system. Convertor systems also include mixing valves and other controls to keep the water temperature from becoming too hot.

An important thing to remember about convertor systems, is that at their point of use, they do NOT use gas. That is, the gas is used by a boiler someplace else, and the steam is piped to the convertor location where it is used to make hot water. This may seem obvious, but a lot of reps have spent a lot of time looking for gas burners on steam convertors!

Gas fired instantaneous units are pretty much limited to residential and very small applications, with the exception of gas booster heaters for commercial dish washing.

Direct Contact Water Heaters

Direct Contact Water Heaters

Direct contact water heating using a pre-mix burner to mix gas and air, ignite it and pass the gas flame directly through the water. Some systems use tanks where the flame is virtually flooded in the water and other systems use a ‘mist’ or ‘spray’ of water into the combustion chamber. These systems are highly efficient, but not all are approved for all applications, because the products of combustion enter into the hot water stream. Currently, these systems are common in commercial laundries, industrial process and locations where it is known that the water will not be used for human consumption. Some units do have potable water ratings, and some units from Kemco and QuikWater even carries the NSF (National Sanitary Foundation) rating. These systems tend to be larger with gas ratings of about 500,000 BTUs/hour and greater.

For more information about Direct Contact Water Heaters

More Information

Energy Audits on Water Heating Systems

Manufacturers

The following is a short list of major manufacturers with helpful information on their web sites. Some select information has been provided below, along with links for additional information on each product line.

A.O. Smith Water Products Co., Inc

A.O. Smith Water Products Co., Inc

World Headquarters

11270 West Park Place

Milwaukee, WI 53224

Telephone: 414-359-4000

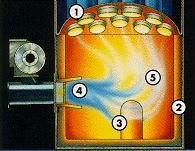

Glass-Lined Storage Tank

Glass-Lined Storage Tank- Proylite 3100 Chamber Wall – Retains heat ensuring cool operation and maximum heat transfer to water, not the room.

- Heat Distribution/Flame Deflector Dome – Distributes heat evenly throughout combustion chamber and flues, eliminating hot spots and uneven heat transfer, resulting in peak operating efficiency and heater life.

- Flame Spreader – Acts like a spray nozzle to distribute flame in combustion chamber. Helps eliminate hot spots and uneven heat transfer.

- Sealed Combustion Chamber

AERCO International

AERCO International

159 Paris Avenue

Northvale, NJ 07647

Telephone: 800-526-0288, 201-768-2400

The AERCO KC-1000 is a 1,000,000 BTU boiler that can produce water up to 200F for a wide variety of applications, including commercial food service dish washing without the need of an additional booster heater. Can also be modularized for any size of space heating demand. Turn down ratio is 14:1, allowing the output to be as low as 70,000 BTUs. Produces precise temperature control, +-2F of set point.Efficiency rating is “93-99%” depending on load.

AERCO unit uses a tower designed, copper tube heat exchanger with low water volume/low mass to produce higher efficiency and rapid response to temperature demand. Burner is a forced convection style; literature says gas pressure must be 8.5″ minimum for high fire; 14″ maximum.

Standard boilers used for water heating in this size may be only 80% efficient. A 13% boost in efficiency with 1,000 CFH input, would save $1.16/hr when gas is at $9.00/MCF.

Bradford-White

Bradford-White

725 Talamore Dr.

Ambler, PA 19002

Telephone: 215-641-9400

Bradford White is pleased to introduce our new Millivolt Commercial Water Heaters The new Millivolt line of MAGNUM Series® commercial water heaters is the industry’s first line of cordless, commercial gas water heaters. This technology enables these units to generate their own energy from the pilot and thermopile assembly to operate the flue damper. This scientific innovation eliminates the need for an external electric source, making installation of a commercial gas water heater easier and less complicated. MAGNUM Series commercial water heaters with Millivolt technology are also easier to operate. They eliminate the nuisance of “lockout” situations by incorporating a continuous pilot, and they utilize a simplified control system that eliminates many of the trouble shooting procedures required with electronic ignition systems. Millivolt commercial water heaters are available in sizes ranging from 38 to 100 gallons

COPPER BRUTE ENERGY SAVER

COPPER BRUTE ENERGY SAVER

- 90,000 Thru 399,000 BTU Indoor Models

- 495,000 Thru 3,080,000 Btu Outdoor Models

- Direct Fired “Fin-Tube” design for maximum efficiency and fast response to demand

- Flexible design allows many installation options

- 160 PSI ASME heat exchanger construction assures safety and quality

- Better than 80% efficiency

- Exceeds ASHRAE 90.1b 1992 energy efficiency standards

- Optional features available

Bradford-Whites new and greatly expanded web site now also includes a site called ‘Right Spec’ which is a comprehensive site for water heater sizing, spec sheets, piping diagrams, and brand name cross-reference guide. The site does require log-in, but it is instant and free.

To go to the Right-Spec web site rightspec.bradfordwhite.com

Laars Heating Systems

Laars Heating Systems

6000 Condor Drive

Moorpark, CA 93021

Telephone: 805-529-2000

Lochinvar Corporation

Lochinvar Corporation

2005 Elm Hill Pike

Nashville, TN 37210

Telephone: 615-889-8900

Raypak Corporate Office (also Rheem and Ruud)

Raypak Corporate Office (also Rheem and Ruud)

and Principal Manufacturing Facility

2151 Eastman Ave.

Oxnard, CA 93030

Telepone: 805-278-5300

Raypak Canada Limited

2805 Slough Street

Mississauga, Ontario Canada L4T 1G2

Telephone: 905-677-7999

Makers of Rheem, Ruud, and RayPak lines of water heaters and boilers

Ray-Pak’s stated advantage:

High efficiency boilers were introduced in response to the energy crisis of the seventies. Most first generation high efficiency boilers were simply standard units that had been hurriedly modified to boost efficiency. These boilers obtained higher efficiencies by permitting steady-state condensation and in the combustion chamber. Failure to adequately project the combustion chamber and heat exchanger from the corrosive effects of condensate meant that most first generation units failed prematurely. The units condensed, eventually corroded, and finally were discarded. Manufacturers learned from their mistakes. They upgraded materials, redesigned heat exchangers and refined their manufacturing techniques.

The second generation of high efficiency boilers, which began to appear in the late eighties, was a vast improvement. However, second generation units still experience damage from condensation. Although the materials used in second generation high efficiency boilers last considerably longer, they will eventually succumb to corrosion.

After two decades of trial-and-error, the boiler industry has finally realized that high efficiency and long product life can only be obtained by preventing condensation from occurring in the combustion chamber. Raypak’s Advanced Design Boiler is the first of a new generation of boilers that can obtain ultra-high efficiency without compromising product life. The “secret” to the ADB’s longevity is that condensation occurs only in a corrosion-resistant secondary heat exchanger. The ADB is designed so that condensation will not occur in the primary heat exchanger or the combustion chamber. The result is an ultra-high efficiency product that lasts.

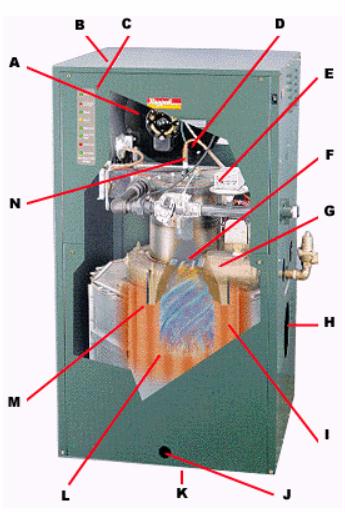

A. Combustion Air Fan with easy-to-adjust combustion air shutter

A. Combustion Air Fan with easy-to-adjust combustion air shutter- B. Weather Proof Jacket The heavy gauge steel exterior jacket is protected with a baked-on UV-resistant Polytuf Powder coat finish

- C. Operation Status Center Central point wiring, standard operating lights, optional full-boiler diagnostics

- D. Vent Pressure Switches Enhance safety by verifying proper burner operation

- E. Up-front Controls Easy access to all controls and gas train components

- F. Advanced Power Burner Industrial-tough, solid metal burner head won’t clog or burn out – and it’s backed with a TEN YEAR UNCONDITIONAL WARRANTY

- G. Rugged All Bronze Header Naturally corrosion resistant. Cast-iron headers with porcelainized water ways are also available

- H. Vent Outlet Flexibility The flue gas outlet can be repositioned in the field to vent from either the back or right side of the unit

- I. Tube Sheet Construction Eliminates the repair and maintenance problems associated with rolling tubes directly into a casting

- J. Viewing Port Allows easy fine-tuning of the power burner

- K. Small Footprint The ADB occupies less than 5.8 sq. ft. of floor space.

- L. Cupro-Nickel Finned Tubes Provides fast, efficient heat transfer with extended tube life

- M. Primary Heat Exchanger Vertical, cylindrical, multi-pass heat exchanger captures all radiant energy, eliminating the need for heavy refractory

- N. Spark to Pilot Ignition The most dependable ignition method available

The Raypak Condensing Heat Exchanger (CHX) – Your Key to Increased Efficiencies and Savings The CHX is a scavenging heat exchanger that has been specifically designed to capture the maximum amount of energy from the ADB’s exhaust gases. When used in low-temperature applications, such as pool heating, the ADB/CHX system can squeeze out an amazing 98% of all heat of combustion energy contained in the flue gases. The CHX is built tough enough to withstand the demanding conditions found in condensing applications. All materials used in the CHX are inherently corrosion resistant and are treated with advanced corrosion-proof coatings for extra protection. The heat exchanger tubes are made of pure copper and are coated with a condensate impervious epoxy enamel. All non-stainless internal fittings are either epoxy coated or are chemical immune. Even the exterior of the jacket, which is fabricated from 21-4C stainless steel, has an extra layer of protection – an electrostatically applied powder coat finish that is baked-on for superior corrosion resistance and extra long life. By segregating condensation from the primary heat exchanger and the combustion chamber, the CHX produces ultra-high efficiency without sacrificing product life.

The Raypak Condensing Heat Exchanger (CHX) – Your Key to Increased Efficiencies and Savings The CHX is a scavenging heat exchanger that has been specifically designed to capture the maximum amount of energy from the ADB’s exhaust gases. When used in low-temperature applications, such as pool heating, the ADB/CHX system can squeeze out an amazing 98% of all heat of combustion energy contained in the flue gases. The CHX is built tough enough to withstand the demanding conditions found in condensing applications. All materials used in the CHX are inherently corrosion resistant and are treated with advanced corrosion-proof coatings for extra protection. The heat exchanger tubes are made of pure copper and are coated with a condensate impervious epoxy enamel. All non-stainless internal fittings are either epoxy coated or are chemical immune. Even the exterior of the jacket, which is fabricated from 21-4C stainless steel, has an extra layer of protection – an electrostatically applied powder coat finish that is baked-on for superior corrosion resistance and extra long life. By segregating condensation from the primary heat exchanger and the combustion chamber, the CHX produces ultra-high efficiency without sacrificing product life.