Air to Air HeatExchanger

Applications

Applications

- Space Heating and Cooling

- Energy Recovery and Management

NOTE: This page is for non-process, non-combustion air heat exchangers. For information on those applications see Regenerative Burners andBoiler Stack Economizer

Overview

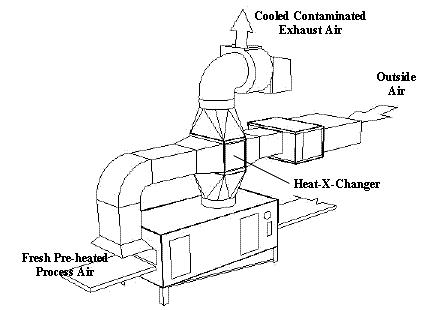

A significant amount of energy used to heat and cool commercial and industrial buildings is used to treat the large quantities of air that moves through the conditioned space. As buildings are built better (tighter and with higher R-values) the mechanically ventilated air becomes an even larger percentage of the total heating and cooling energy cost. In order to maintain good indoor air quality, the air must be turned over (dumped) but the energy in the air does NOT need to be wasted. Air to Air Heat exchangers can be used to recover energy in the ventilation air that is leaving the building and used to pre-heat (pre-cool) the fresh incoming air. As much as 80% of the energy can be recovered, which can represent up to half of the total heating and cooling costs for many buildings.

How They Work

How They Work

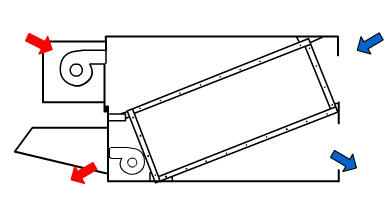

Air to Air Heat Exchangers are designed to allow two air streams to come into close contact with each other – close enough that the energy can be exchanged, but not so close that the contaminates are exchanged. Because heat always seeks cold, heat will always flow into the colder air stream – given the right conditions such as a low-resistance heat exchanger and a LOT of surface area. Air has a very low “specific heat” (0.018 BTUs per cubic foot) which means it doesn’t carry a lot of energy per cubic foot, especially when the temperature difference is small such as in space conditioning applications. Therefore, it takes a LOT of CFM and/or a large heat exchanger surface to make the exchange. The more heat exchanger surface that is available, and the lower the material resistance, the more efficient the exchanger. Some heat exchangers also include an ‘enthalpy wheel’. Enthalpy refers to the energy contained in water vapor. Enthalpy wheels allow some of the humidity to be exchanged also. This can be desired to keep winter air moister and summer air dryer. However, there is also a risk of contamination with enthalpy wheels if both air streams are not relatively clean.

Types of Units

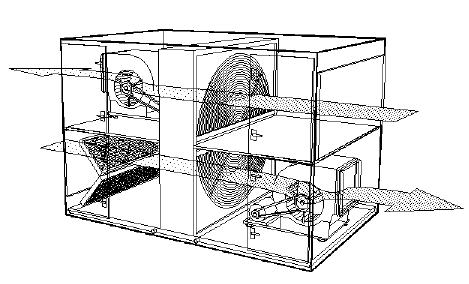

Moving or Wheel Energy or Enthalpy Recovery Wheel Systems

use a corrugated material shaped like a wheel turning at 15 to 20 rpm to recover 50 to 80% of thermal energy. These wheels can also be made of a desiccant material that helps to transfer moisture along with temperature. Wheels should never be used in areas with any issues of cross contamination or where there are indoor air quality issues. Wheel type products are more maintenance prone than fixed plate systems, but offer superior moisture transfer or enthalpy transfer. Cross contamination can be as low as 2% of air stream. Polymer Fixed Plate Energy Recovery

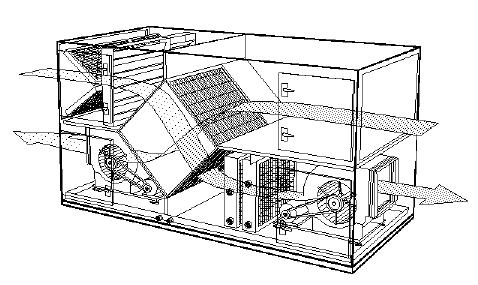

The standard polymer energy recovery module is engineered with a non corroding, sanitary, monolithic heat exchanger. The standard heat exchanger typically will not let contaminants or water transfer or permit any cross contamination. In extreme applications, the standard heat exchanger can be hosed down for cleaning if needed. Typically no cleaning or maintenance is needed by a standard heat exchanger for the entire life of the system. This means 15 to 20 years in service with no time or money spent to maintain the unit.  Desiccant Fixed Plate Enthalpy and Energy Recovery The standard desiccant enthalpy module is engineered to provide moisture and temperature transfer without any moving parts. These standard desiccant enthalpy modules are not engineered to handle extreme moisture conditions, but when used in partially conditioned air streams can provide effective secondary energy and enthalpy transfer. Typically, an engineered system would use a primary standard polymer energy recovery module to reduce temperature and moisture in series with a standard desiccant enthalpy module. The standard desiccant enthalpy module can provide up to 50% moisture transfer and additional thermal energy transfer. It should be understood that any enthalpy recovery system has the potential for cross contamination. Fixed plate enthalpy recovery systems have far less potential than wheel or moving enthalpy recovery system. For more on Desiccants see Desiccant Dehumidification

Desiccant Fixed Plate Enthalpy and Energy Recovery The standard desiccant enthalpy module is engineered to provide moisture and temperature transfer without any moving parts. These standard desiccant enthalpy modules are not engineered to handle extreme moisture conditions, but when used in partially conditioned air streams can provide effective secondary energy and enthalpy transfer. Typically, an engineered system would use a primary standard polymer energy recovery module to reduce temperature and moisture in series with a standard desiccant enthalpy module. The standard desiccant enthalpy module can provide up to 50% moisture transfer and additional thermal energy transfer. It should be understood that any enthalpy recovery system has the potential for cross contamination. Fixed plate enthalpy recovery systems have far less potential than wheel or moving enthalpy recovery system. For more on Desiccants see Desiccant Dehumidification

More Information

Heat Recovery General Energy Recovery Wheels

Manufacturers

Building Performance Equipment, Inc. 6 West Court Beacon Hill, North Wilmington, DE 19810 Telephone : 302-475-7025 www.lowkwh.com XeteX, Inc. 3530 East 28th Street Minneapolis, MN 55406 Telephone: 612-724-3101 www.xetexinc.com SEMCO, Inc. 1800 East Pointe Drive Columbia, MO 65201-3508 Telephone: 314-443-1481 Web site: www.semcoinc.com See also Desiccant Dehumidification for more vendors Source: Text Bob Fegan 1/2009; Types of Units text from the BPE web site linked above 1/2004; some images from XeteX web site linked above 1/2004;

© 2008 Energy Solutions Center400 N. Capitol Street NWWashington, DC 20001 All rights reserved. Legal Contact our webmaster