Continuous Rotary Cooker – Canned Products, Retort System, Continuous

Continuous Rotary Cooker – Canned Products, Retort System, Continuous

Industry: Fruit and Vegetables (3114) Meat (NAICS 3116)

NAICS process:

311421 Canned Fruit and Vegetables

311422 Canned Specialty Products

311612 Meat Processed from Carcasses

Process Brief: Canned products are sterilized by heat after they are sealed

Energy source: Steam/Natural Gas

Energy Intensity: 100-300 Btu/lb

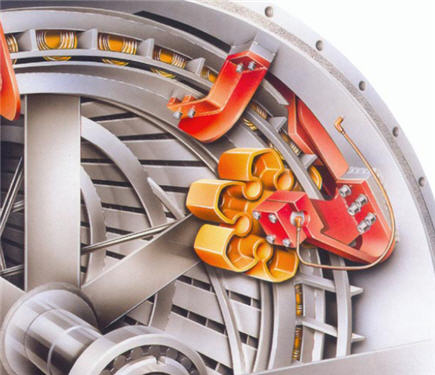

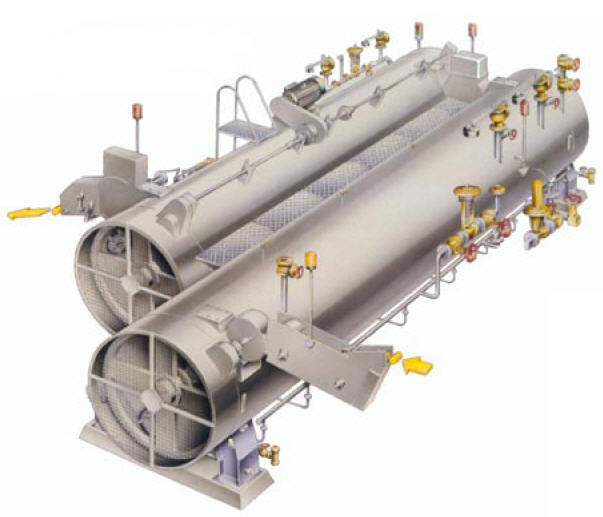

Retort systems sterilize canned products after they are sealed. Continuous rotary cookers use two chambers that are shaped like horizontal cylinders. The can transfer mechanisms for the cylinders are linked so that system is always synchronized and the speed of the transfer mechanism is the primary means of controlling the process. The first chamber is the sterilizer and the second is the cooler. A continuous line of cans enters the sterilizer and follows a spiral path during which the can is heated to specification. The cans feed directly into the cooler and follow a spiral path while they are cooled. At the entry and exit points the cans pass through a rotary pressure sealed transfer valve that keep steam inside the system and allow the sterilizer to be pressurized while maintaining a continuous process. The spiral track is constructed so that the can rotates as it travels, which enhances even heat transfer. Some systems achieve specific heating and cooling patterns by employing multiple sterilizing or cooling chambers so the system may have as many as five cylinders.

The continuous rotary cooker uses slightly less steam than the crateless retort but its main advantages are that it requires less labor and material handling. The disadvantage of the continuous rotary cooker is that a particular system can handle a smaller range of cans than crateless systems.

Manufacturers

FMC FoodTech Chicago

200 East Randolph

Chicago, IL 60601

Telephone: 312-861-6000

Web site: www.fmctechnologies.com

Source: Overview GRI-03/0075; FMC Photos and graphics from http://www.fmctechnologies.com/FoodTech/FruitsandVegetables/InContainerSterilizers/RotaryPressure.aspx 3/2007;