Rising/Falling Film Plate – Plate Evaporation – Steam-Based

Industry: Fruit and Vegetables (NAICS 3114) Dairy (NAICS 3115)

NAICS process:

311411 Frozen Fruit and Vegetables

311421 Canned Fruit and Vegetables

311514 Evaporated and Condensed Milk

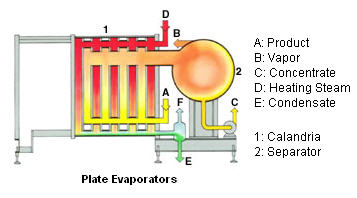

Process Brief: Water is removed by passing a film of the product across heated plates.

Energy source: Steam/natural gas

Energy Intensity:

Falling Plate

The falling plate evaporator evolved from the rising/falling plate evaporator by eliminating the rising plate. Incorporating only the falling plate reduces system complexity and reduces process time, which reduces heat-related product degradation. The falling plate system uses larger vapor ports to deliver more product across the plate because flow is assisted by gravity. Systems can achieve evaporation rates of 60,000 lb per hour. Multiple effect systems can achieve high moisture removal rates. Falling plate evaporators are used to concentrate fruit juices and evaporated milk.

Rise/Fall Plate

The rising/falling-film plate evaporator uses one or more sets of rising/falling and steam plates to cause water to evaporate from a product. Each set includes a rising plate, steam plate, falling plate, and another steam plate; and these plates are assembled in a single housing. The product is fed into the rising film plate at a temperature slightly above the evaporation point to achieve distribution across the width of the plate. Heat from the steam plate boosts evaporation and the remaining product flows through a slot to falling plate where gravity assists the flow of the film and the evaporation continues. Multiple sets of plates are used to achieve additional evaporation.

Rising/falling film plate evaporators tend to be cheaper to build than tubular evaporators and energy efficiencies are comparable. One advantage is that systems can be constructed to fit under ceilings that are 12-13 feet in height while tubular systems require 30-40 feet. Rising/falling plate systems are often used to concentrate juices and dairy products because retention times are short and temperatures (about 195°F) are lower, which preserves product quality. Systems can be designed to achieve evaporation rates of 30,000-35,000 pounds per hour.

Manufacturers

Niro Inc.

9165 Rumsey Road

Columbia, MD 21045

Telephone: 410-997-8700

Web site: www.niroinc.com