Overview

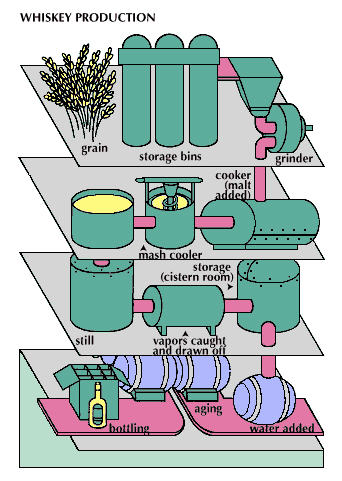

Distilled spirits can be produced by a variety of processes. Typically, in whisky production, grains are mashed and fermented to produce an alcohol/water solution, that is distilled to concentrate the alcohol. For whiskies, the distilled product is aged to provide flavor, color, and aroma. This discussion will be limited to the production of Bourbon whisky.

Whisky Production

Grain Handling And Preparation –

Distilleries utilize premium cereal grains, such as hybrid corn, rye, barley, and wheat, to produce the various types of whisky and other distilled spirits. Grain is received at a distillery from a grain handling facility and is prepared for fermentation by milling or by malting (soaking the grains to induce germination). All U.S. distillers purchase malted grain instead of performing the malting process onsite.

Grain Mashing –

Mashing consists of cooking the grain to solubilize the starch from the kernels and to convert the soluble starch to grain sugars with barley malt and/or enzymes. Small quantities of malted barley are sometimes added prior to grain cooking. The mash then passes through a noncontact cooler to cool the converted mash prior to entering the fermenter.

Fermentation –

The converted mash enters the fermenter and is inoculated with yeast. The fermentation process, which usually lasts 3 to 5 days for whisky, uses yeast to convert the grain sugars into ethanol and carbon dioxide. Congeners are flavor compounds which are produced during fermentation as well as during the barrel aging process. The final fermented grain alcohol mixture, called “beer”, is transferred to a “beer well” for holding. From the beer well, the beer passes through a preheater, where it is warmed by the alcohol vapors leaving the still, and then to the distillation unit. The beer still vapors condensed in the preheater generally are returned to the beer still as reflux.

Distillation –

The distillation process separates and concentrates the alcohol from the fermented grain mash. Whisky stills are usually made of copper, especially in the rectifying section, although stainless steel may be used in some stills. Following distillation, the distilled alcohol spirits are pumped to stainless steel tanks and diluted with demineralized water to the desired alcohol concentration prior to filling into oak barrels and aging. Tennessee whisky utilizes a different process from Bourbon in that the distillate is passed through sugar maple charcoal in mellowing vats prior to dilution with demineralized water.

Grain and Liquid Stillage (“Dryer House Operations”) –

In most distilleries, after the removal of alcohol, still bottoms (called whole stillage), are pumped from the distillation column to a dryer house. Whole stillage may be sold, land applied (with permitting), sold as liquid feed, or processed and dried to produce distillers dried grains (DDG) and other secondary products. Solids in the whole stillage are separated using centrifuges or screens; the liquid portion (thin stillage) may be used as a backset or concentrated by vacuum evaporation. The concentrated liquid may be recombined with the solids or dried. Drying is typically accomplished using either steam-heated or flash dryers.

Warehousing/Aging –

Aging practices differ from distiller to distiller, and even for the same distiller. Variations in the aging process are integral to producing the characteristic taste of a particular brand of distilled spirit. The aging process, which typically ranges from 4 to 8 years or more, consists of storing the new whisky distillate in oak barrels to encourage chemical reactions and extractions between the whisky and the wood. The constituents of the barrel produce the whisky’s characteristic color and distinctive flavor and aroma. White oak is used because it is one of the few woods that holds liquids while allowing breathing (gas

exchange) through the wood. Federal law requires all Bourbon whisky to be aged in charred new white oak barrels. The oak barrels and the barrel environment are key to producing distilled spirits of desired quality. The new whisky distillate undergoes many types of physical and chemical changes during the aging process that removes the harshness of the new distillate. As whisky ages, it extracts and reacts with constituents in the wood of the barrel, producing certain trace substances, called congeners, which give whisky its distinctive color, taste, and aroma.

Barrel environment is extremely critical in whisky aging and varies considerably by distillery, warehouse, and even location in the warehouse. Ambient atmospheric conditions, such as seasonal and diurnal variations in temperature and humidity, have a great affect on the aging process, causing changes in the equilibrium rate of extraction, rate of transfer by diffusion, and rate of reaction. As a result, distillers may expose the barrels to atmospheric conditions during certain months, promoting maturation through the selective opening of windows and doors and by other means.

Distillers often utilize various warehouse designs, including single- or multistory buildings constructed of metal, wood, brick, or masonry. Warehouses generally rely upon natural ambient temperature and humidity changes to drive the aging process. In a few warehouses, temperature is adjusted during the winter. However, whisky warehouses do not have the capability to control humidity, which varies with natural climate conditions.

Blending/Bottling –

Once the whisky has completed its desired aging period, it is transferred from the barrels into tanks and reduced in proof to the desired final alcohol concentration by adding demineralized water.

Following a filtration process that renders it free of any solids, the whisky is pumped to a tank in the bottling house, bottled, and readied for shipment to the distributors.

Major Processes

Major Equipment

Natural Gas Technologies