Overview

Overview

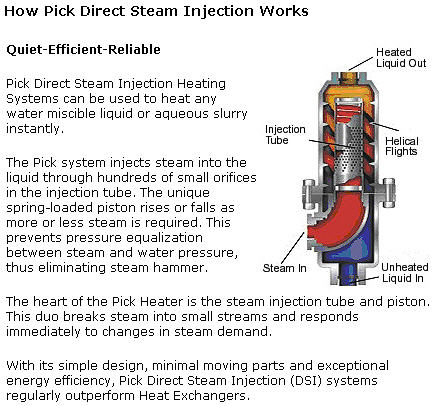

Direct Steam Injection is much more energy efficient than its competitive method, Indirect Heat Exchange. In Direct Steam Injection, steam is instantly blended into the process fluid, resulting in 100% heat transfer with full use of both the latent and sensible heat. There is no condensate to trap and recover. 100% of your costly BTU’s are used. Steam under pressure is injected directly into the liquid. Because 100% of the steam is instantly condensed into the liquid, 100% of the BTU’s are used.

Because Direct Steam Injection systems are 100% energy efficient, it can save up to 28% of the fuel required with indirect heat exchangers. The fuel savings will pay for the heater many times over during the life of the system.

But, What Happens To The Condensate?

Indirect heat exchangers do not consume steam, resulting in condensate. The condensate is then discharged through a trap and returned to a flash tank. A portion of the condensate is lost due to flashing and must be replaced with cold water. With Direct Steam Heaters, you simply do not have to give condensate a second thought. The condensate is USED, not lost. It contributes to the discharge stream. The total water consumption is unchanged. Elimination of flash losses yields improved energy efficiency and reduced operating costs. Steam is completely consumed and no condensate is returned. Flash losses are eliminated, as is the need for a flash tank.

Manufacturers

Pick Heaters, Inc.

730 S. Indiana

P.O. Box 516

West Bend, WI 53095

Telephone: 800-233-9030

Web site: www.pickheaters.com

Source: Pick web site at http://www.pickheaters.com/energy_efficiency.cfm 3/2007;