Turbulators

Introduction

Introduction

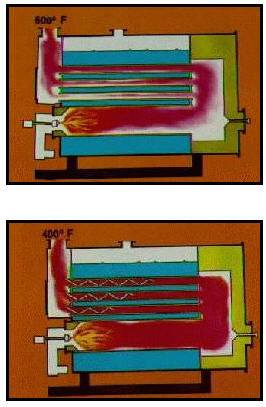

In a firetube boiler, hot combustion gases pass through long, small-diameter tubes, where heat is transferred to water through the tube walls. Firetube boilers are categorized by their number of “passes,” or the number of times that the hot combustion gases travel across the boiler heat-exchange surfaces. For example, a two-pass boiler provides two opportunities for hot gases to transfer heat to the boiler water. Hot combustion gases enter the tubes in a turbulent flow regime, but within a few feet, laminar flow begins and a boundary layer of cooler gas forms along the tube walls. This layer serves as a barrier, retarding heat transfer.

Turbulators, which consist of small baffles, angular metal strips, spiral blades, or coiled wire, are inserted into the boiler tubes to break up the laminar boundary layer. This increases the turbulence of the hot combustion gases, and the convective heat transfer to the tube surface. The result is improved boiler efficiency. Turbulators are usually installed on the last boiler pass. Turbulator installers can also balance gas flow through the tubes by installing longer turbulators in the uppermost tubes. This practice increases the effectiveness of the available heat-transfer surface by eliminating thermal stratification and balancing the gas flow through the firetubes.

Every 40°F reduction in the boiler flue gas temperature results in a 1% boiler-efficiency improvement.

Operation

Turbulators can be a cost-effective way to reduce the stack temperature and increase the fuel-to-steam efficiency of single-pass horizontal return tubular (HRT) brick-set boilers and older two- and three-pass oil and natural-gas-fueled firetube boilers. Turbulators are not recommended for four-pass boilers or coalfired units. A four-pass unit provides four opportunities for heat transfer. It has more heat exchange surface area, a lower stack temperature, higher fuel-to-steam efficiency, and lower annual fuel costs than a two- or three-pass boiler operating under identical conditions. New firetube boilers perform better than older two and three-pass designs.

Turbulators can also be installed to compensate for efficiency losses when a fourpass boiler is being converted to a two-pass boiler because of door warpage and loose and leaking tubes.

Turbulators are a substitute for a more costly economizer or air-preheater. They are simple, easy to install, and low cost. Their installed cost is about $10 to $15 per boiler tube. Current turbulator designs do not cause significant increase in pressure drops or contribute to soot formation in natural-gas-fired boilers. Turbulators are held in place with a spring lock and are easily removed to allow for tube brushing.

Turbulators come in various lengths and widths and should be installed by a qualified installer. To avoid combustion problems, the boiler burner should be re-tuned after the turbulators have been installed. The installer must also verify that the stack temperature does not fall below the flue gas dew point.

More Information

Manufacturers

Fuel Efficiency, LLC.

P.O. Box 271 – Dept B

Davis Industrial Park

Clyde, NY 14433 USA

Telephone: ![]() 315-923-2511

315-923-2511

Fax: 315-923-9182

Go to their web site at www.fuelefficiencyllc.com

Source: Text from DOE “Improving Steam System Performance: A Sourcebook for Industry” 2004; image from www.fuelefficiencyllc.com web site 2-2005;