Cleaver-Brooks Hawk

Hawk ICS

Hawk ICS

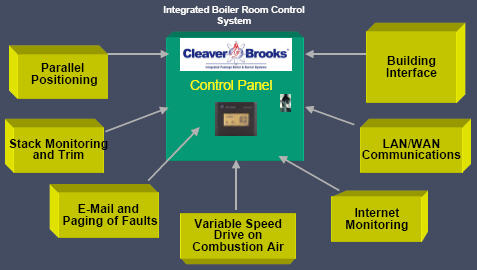

The CB Hawk ICS is a totally integrated control system embodying precise boiler/burner management control and safety with logic based ancillary devices and functions. The result is a coordinated system which maximizes efficiency, reduces operating costs, and increases productivity; delivering critical real time and historic information with the touch of a screen! Using today’s state of the art technology, the CB Hawk ICS soars to a new level, combining a highly powered high speed processor with sophisticated inter-communication protocol (“Ethernet/IP”) for controlling and monitoring all of the important boiler system operating and safety functions in one synergistic, expandable package.

Key features and functions in base package:

-

Integrated burner management control from pre-purge to post-purge.

-

Flame scanning and amplifying. Processing inputs from solid state sensors measuring pressure and/or temperature.

-

Firing rate control

-

Thermal shock protection

-

Night/day setback

-

Outdoor reset

-

Remote setpoint

-

Lead/lag control for multiple boilers (option)

-

Variable Speed Drive (VSD) capability for combustion air and/or boiler feed pump(s)

-

Auxiliary inputs available for monitoring boiler related devices and conditions.

-

Human machine Interface (HMI) for setting operating conditions and accessing all operating parameters and alarm history. All this with the touch of a screen!

-

Local electronic communication

Monitoring Capabilities Include:

-

Operating parameters, faults and selected I/O’s

-

Stack temperature

-

Combustion air temperature

-

Combustion fan RPM

-

Combustion air pressure

-

Efficiency

-

O2

-

Steam pressure and flow

-

Water temperature

-

Fuel flow

-

Water level

-

Firing rate

-

Faults and fault history

Optional Features and functions include:

-

Parallel control of fuel and air using motor actuator drives; minimizing linkages.

-

Water level monitoring and alarming

-

O2 monitoring and/or trimming

-

Ethernet and internet communication

-

E-mailing, paging and on-line trouble shooting

-

Building management system interfacing

-

Backlit touch screen (optional)

LevelMaster

The basis of design called for use of a microprocessor based control system which embraced six (6) important design criteria: Simplicity, Safety, Security, Dependability, Adaptability and Environment. The result is the revolutionary C-B Level Master low water cutoff and pump control using the proven magnetostrictive technology (used for many years in various industries for measuring level and distance relationships) in conjunction with a solid state sensor and microprocessor based controller.

Simplicity

- Magnetostrictive technology eliminating levers and switches

- Non contact and non wearing titanium float

- User friendly controller with easy to read parameters/alarms

- Uses single phase power to a central connection point

- Controller uses plug-in connectors for easy exchange

- Can be used for on/off pump operation or modulating fee

Safety

-

Column blowdown reminders and message it’s been done properly or improperly

-

System allows for checking the auxiliary low water cutoff and its proper operation

-

Float movement is constantly checked; stuck float shuts boiler down

-

Electrics and microprocessor circuits checked several times per second for continuity and performance

-

Low water shutdown and alarming

-

High and low water warnings

-

Alarm and blowdown history logging with time and date stamps

Security

-

Password protected regarding level settings and alarm and blowdown history files

-

On going level indication; easy to see and read exactly

Dependability

-

Alarm and blowdown history logging

-

Blowdown reminders

-

Constant checking of electrics/electronics

-

Remote communication access (RS-232)

Adaptability

-

Direct replacement and retrofittable to all makes of boilers

-

On/off or modulating boiler feed control with same unit

Environment

-

C-B Level Master eliminates the mercury!

More Information

Go to the Cleaver-Brooks web site at www.cleaver-brooks.com

Source: Cleaver-Brooks web site and Elizabeth Brown, Marketing Communications for Cleaver-Brooks 1/2005;